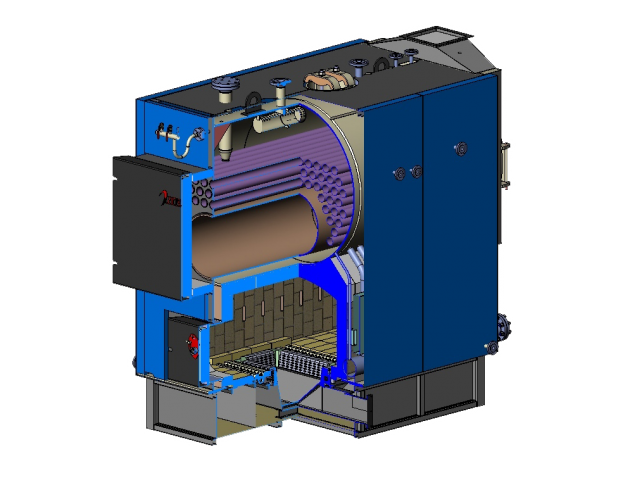

Alekot steam boilers are designed to produce steam, which is used in various technological processes. The range of modulation of installation is from 30% to 100% which allows to use it more rationally. The boiler can work on sawdust, shavings, chips, bark, husks, straw. The furnace is lined with fireclay bricks and, as a result, the service life of the installation increases. Cast iron grate is made with the addition of chromium, which allows you to use them at high temperatures. The multicyclone used in our installation catches harmful particles of the gases which are in a suspended condition. This allows to achieve minimal emissions into the atmosphere that meet European environmental standards. The fuel storage is designed to ensure uninterrupted operation of the boiler for 2-3 days.

| Parameters | Alekot KPm-series with automated feeding | |||||

| Fuel type | Wood chips, shavings, peat, sunflower husk, pellets, WID… | |||||

| Moisture content, % | up to 35 | |||||

| Fuel dimensions (max), mm | 10х40х125 | |||||

| Heat capacity, kW | 0,5 | 1 | 1,5 | 2,0 | 2,5 | 3 |

| Outlet water temperature, °С | 110-194 | |||||

| Operating pressure, MPa | 0,6-1,4 | |||||

| Efficiency, % | 87 | |||||

| Outlet flue gas temperature, °С | 160 | |||||

| Modulation range, % | 30-100 | |||||

| Sound level, dB | 80 | |||||

| Utilization time, h/year | 8 000 | |||||

| Operating lifetime, years | 20 | |||||

| Power supply | 380 V; 50 Hz | |||||